Air, Minyak, Sabun, mesin pengisian AdBluePROTON EE-ELEKTRONIKA d.o.o

XFR1000

Air, Minyak, Sabun, mesin pengisian AdBlue

PROTON EE-ELEKTRONIKA d.o.o

XFR1000

Tahun pembuatan

2025

Keadaan

Baharu

Lokasi

Šašinovec

Gambar menunjukkan

Tunjukkan peta

Data mesin

- Nama mesin:

- Air, Minyak, Sabun, mesin pengisian AdBlue

- Pengeluar:

- PROTON EE-ELEKTRONIKA d.o.o

- Model:

- XFR1000

- Tahun pembuatan:

- 2025

- Keadaan:

- baharu

- Fungsi:

- berfungsi sepenuhnya

Harga & Lokasi

- Lokasi:

- Krcevina 4, 10360 Soblinec, Hrvatska

Hubungi

Butiran teknikal

- Lebar keseluruhan:

- 2,400 mm

- Jumlah panjang:

- 15,000 mm

- Jumlah ketinggian:

- 2,800 mm

- Tekanan:

- 8 palang

- Kuasa:

- 10.9 kW (14.82 kuasa kuda)

- Berat kosong:

- 6,400 kg

- Voltan masuk:

- 400 V

- Berat pengisian (min.):

- 200 g

- Berat pengisian (maks.):

- 5,000 g

Butiran tawaran

- ID iklan:

- A17231422

- Kemas kini:

- terakhir pada 25.09.2025

Penerangan

XFR 1000

Liquid Media Filling Line

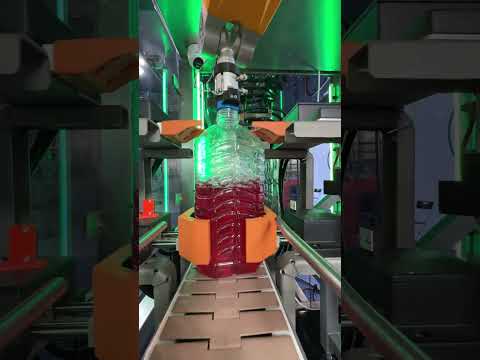

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Bsdouq Nv Tepfx Ablscw

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Liquid Media Filling Line

A fully automated liquid media filling line featuring robotic capping, automated handle placement, dual-sided labelling, optical quality control, and pallet wrapping.

An end-to-end solution covering the entire process, from bottle blowing to the palletizing and wrapping of filled bottles.

XFR LIQUILOAD

It enables optimal filling speeds for bottles of varying characteristics and liquids of different viscosities.

The machine’s easy configuration for different bottle types and corresponding liquids ensures quick adaptation to market demands.

• Capability to increase the number of nozzles

• Nozzles designed to prevent foaming of the liquid

• 800 to 4,000 filled bottles per hour

• Servo-driven nozzle positioning

• Easy configuration of new programs

XFR BOTTLELOCK

The machine segment performs fully automated capping of filled bottles.

Designed to accommodate various cap types, simplifying machine adjustments for seamless operation.

• Cap type adaptability

• Robotic bottle capping

• Optical inspection

• 800 to 2,000 capped bottles per hour

XFR HANDLEGRIP

The automatic robotic placement of handles on bottles, while they move continuously towards the labeling machine, ensures seamless and uninterrupted operation.

• Adaptability to different handle types

• Robotic handle application on bottles

• Optical inspection for handle orientation verification

• Capability to attach handles with a funnel

XFR LABELFLOW

The machine applies the appropriate labels to both sides of the bottle, creating a finished appearance.

In the next phase, the labelled bottles undergo optical inspection.

• HERMA labelling system

• Simplified label type changeover

• Servo-driven for enhanced labeling precision

• Monitoring of remaining labels with operator alerts

OPTIONAL PARTS:

1. OPTICAL INSPECTION

Industrial cameras with integrated lighting and pneumatic ejection system.

2. PICK AND PLACE ROBOT

6-axis robot equipped with a 160 kg gripper for the current handling of 8 bottles onto a Euro pallet.

3. PALLETIZING

Palletizer with automatic pallet feeding via a roller conveyor to the bottle stacking area.

4. PALLET WRAPPING

The automatic pallet wrapper applies stretch film to palletized products, securing them for easier and safer transport.

5. FINISHED GOODS STORAGE

Finished pallets are transported to the warehouse via a metal roller conveyor.

6. REMOTE CUSTOMER SUPPORT

We provide remote support to ensure optimal machine performance.

7. ADDITIONAL OPTIONS

Automated data integration with ERP systems; RFID login; NFC detection of parts and tools; magnetically mounted tools.

8. MACHINE CONFIGURATION

Segments can operate independently or as an integrated solution, depending on the client's specific needs.

Bsdouq Nv Tepfx Ablscw

Proton EE-Elektronika d.o.o.

MachinFlex d.o.o.

Pembekal

Nota: Daftar secara percuma atau log masuk, untuk mengakses semua maklumat.

Didaftarkan sejak: 2020

Hantar permintaan

Telefon & Faks

+385 43 3... iklan

Iklan-iklan ini juga mungkin menarik minat anda.

Iklan kecil

Jerman

Jerman

9,760 km

Mesin membuat beg

Honsel & Co.722

Honsel & Co.722

Iklan kecil

Jerman

Jerman

9,760 km

Mesin pasta

JuwelPQ6-SU/PQ3-SU

JuwelPQ6-SU/PQ3-SU

Iklan kecil

Jüri

Jüri

8,885 km

Debarker

Valon Kone OYVK-550-Combi 2R/480(620)

Valon Kone OYVK-550-Combi 2R/480(620)

Iklan kecil

Ostrołęka

Ostrołęka

9,000 km

Pengeluaran susu dan produk susu

MargoPasteryzator

MargoPasteryzator

Iklan kecil

Ieriķi

Ieriķi

8,831 km

Mesin pengeluaran palet

FORMAPBS M4

FORMAPBS M4

Iklan kecil

Bad Lippspringe

Bad Lippspringe

9,868 km

GRILLOMAX OVEN

GRILLOMAX GRILLSTATIONGRILLSTATION

GRILLOMAX GRILLSTATIONGRILLSTATION

Iklan kecil

Thamsbrück

Thamsbrück

9,747 km

Pengisian dan pengedap supositoria

CP-Citopac Technology and Packaging GmbHFKS-10

CP-Citopac Technology and Packaging GmbHFKS-10

Iklan kecil

Lagedi

Lagedi

8,884 km

Bekas tekan

HusmannSPB 20 SEN-E

HusmannSPB 20 SEN-E

Iklan kecil

Italia

Italia

9,657 km

Mesin untuk menghasilkan minuman

Bottling Alfatek beerBottling Line Complete Bottling

Bottling Alfatek beerBottling Line Complete Bottling

Iklan kecil

Breda

Breda

10,143 km

Talian paip PVC WEBER DS 8.5 sehingga 160 mm

WeberWEBER DS 8.5

WeberWEBER DS 8.5

Iklan anda telah berjaya dipadamkan

Berlaku ralat