Balenmasin dengan penutup pra-tekan LP 50 EH1Baler dengan penutup pra-pemampatan LP 50 EH1Presona AB

LP 50 EH1

Balenmasin dengan penutup pra-tekan LP 50 EH1Baler dengan penutup pra-pemampatan LP 50 EH1

Presona AB

LP 50 EH1

Tahun pembuatan

2005

Keadaan

Terpakai

Lokasi

Belanda

Gambar menunjukkan

Tunjukkan peta

Data mesin

- Nama mesin:

- Balenmasin dengan penutup pra-tekan LP 50 EH1Baler dengan penutup pra-pemampatan LP 50 EH1

- Pengeluar:

- Presona AB

- Model:

- LP 50 EH1

- Tahun pembuatan:

- 2005

- Keadaan:

- dibaik pulih bengkel (terpakai)

- Fungsi:

- berfungsi sepenuhnya

- Jam operasi:

- 30,408 h

Harga & Lokasi

- Lokasi:

- , Belanda

Hubungi

Butiran teknikal

- Daya penekanan:

- 50 t

- Lebar bukaan pengisian:

- 1,100 mm

- Panjang bukaan pengisian:

- 1,250 mm

- Lebar bale:

- 1,100 mm

- Ketinggian bal:

- 720 mm

- Berat bale:

- 550 kg

- Berat keseluruhan:

- 16,000 kg

- Kapasiti tangki minyak:

- 600 l

- Tahun pembaikan besar terakhir:

- 2024

Butiran tawaran

- ID iklan:

- A17766606

- Kemas kini:

- terakhir pada 20.06.2025

Penerangan

Technical data baler:

Manufacturer Presona AB

Type LP 50 EH1

Year of construction 2005

Operating hours 30,408 hours, as of April

Number of pressed bales 198,059 as of April

Pressing force main press 50 tonnes

Specific pressing force 63 N/cm²

Theoretical throughput capacity 530 m³/hour

Throughput capacity under operating conditions 260 m³/hour

Dimensions of feed chute 1,250 x 1,100 mm

Bale chamber volume 2.2 m³

Bale dimensions 1,100 x 720 mm, variable length

Drive power 22 kW

Tying 5-fold vertical, fully automatic

Throughput rates with a

bulk density of 30 kg/cbm 6 up to 7 tonnes/hour

Bulk weight of 50 kg/cbm 7 up to 9 tonnes/hour

Bulk weight of 100 kg/cbm 11 up to 14 tonnes/hour

Bale density (paper/newspapers) 400 to 550 kg/m³

Hydraulic oil tank capacity 600 litres

PLC control Telemecanique TSX Micro

Schneider Magelis control panel

Effective transport dimensions excl. baler 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight press approx. 16 tonnes

Condition of the baler:

The machine was partial overhauled in our workshop and general maintenance work was carried out. After completion of the overhaul work, the press was tested during operation and is available for sale at short notice.

The following overhaul work was carried out:

General work:

Machine cleaned, derusted, primed, partially painted

Wire entry marks in the press channel feed-throughs welded shut and smoothed

Hydraulic unit:

Hydraulic oil tank emptied, tank cleaned, new oil filled

Oil filter and air filter replaced

Gbjdpfx Aou Thhrofyjh

Leaky oil sight glass on hydraulic oil tank replaced

All hydraulic hoses replaced

Electrics:

English language installed in the programme menu

Two key switches in the control panel replaced

Control cabinet replaced

Signal lamp on the control cabinet replaced

Flaps end switch replaced

Electrical system of the turbulator replaced, connected and tested

Press ram:

All four rollers removed from the press ram and replaced

Main hydraulic cylinder dismantled, disassembled and partially overhauled, cylinder tube honed, complete seal set replaced, leak test performed

All plastic wear pads on the press ram replaced

Pre-press:

Both bearings on the pre-press shaft replaced.

Both hydraulic cylinders dismantled, disassembled and partially overhauled, both cylinder tubes honed, complete seal sets replaced, leak test performed.

Scraper flap on the pre-press replaced.

Binding system:

Two complete needles with wire deflection rollers replaced

Needles adjusted and set

All wire deflection rollers in the needle heads replaced

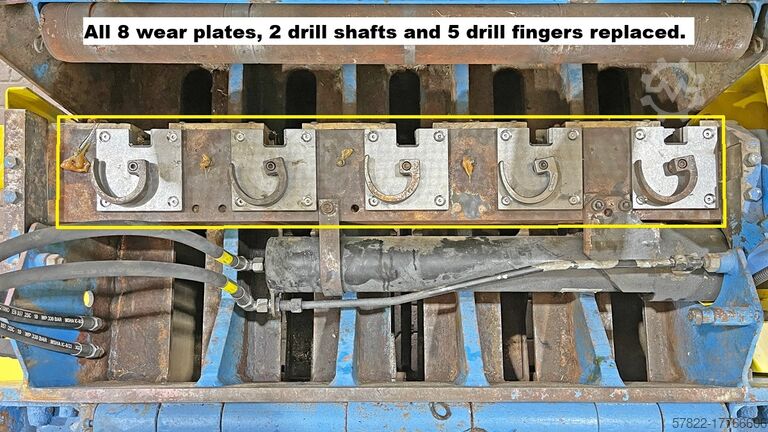

Drill fingers replaced

Two drill shafts replaced

All 8 wear plates on the Drillomat, under the drill fingers, replaced

Scope of delivery:

Only the baler will be sold.

The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Manufacturer Presona AB

Type LP 50 EH1

Year of construction 2005

Operating hours 30,408 hours, as of April

Number of pressed bales 198,059 as of April

Pressing force main press 50 tonnes

Specific pressing force 63 N/cm²

Theoretical throughput capacity 530 m³/hour

Throughput capacity under operating conditions 260 m³/hour

Dimensions of feed chute 1,250 x 1,100 mm

Bale chamber volume 2.2 m³

Bale dimensions 1,100 x 720 mm, variable length

Drive power 22 kW

Tying 5-fold vertical, fully automatic

Throughput rates with a

bulk density of 30 kg/cbm 6 up to 7 tonnes/hour

Bulk weight of 50 kg/cbm 7 up to 9 tonnes/hour

Bulk weight of 100 kg/cbm 11 up to 14 tonnes/hour

Bale density (paper/newspapers) 400 to 550 kg/m³

Hydraulic oil tank capacity 600 litres

PLC control Telemecanique TSX Micro

Schneider Magelis control panel

Effective transport dimensions excl. baler 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight press approx. 16 tonnes

Condition of the baler:

The machine was partial overhauled in our workshop and general maintenance work was carried out. After completion of the overhaul work, the press was tested during operation and is available for sale at short notice.

The following overhaul work was carried out:

General work:

Machine cleaned, derusted, primed, partially painted

Wire entry marks in the press channel feed-throughs welded shut and smoothed

Hydraulic unit:

Hydraulic oil tank emptied, tank cleaned, new oil filled

Oil filter and air filter replaced

Gbjdpfx Aou Thhrofyjh

Leaky oil sight glass on hydraulic oil tank replaced

All hydraulic hoses replaced

Electrics:

English language installed in the programme menu

Two key switches in the control panel replaced

Control cabinet replaced

Signal lamp on the control cabinet replaced

Flaps end switch replaced

Electrical system of the turbulator replaced, connected and tested

Press ram:

All four rollers removed from the press ram and replaced

Main hydraulic cylinder dismantled, disassembled and partially overhauled, cylinder tube honed, complete seal set replaced, leak test performed

All plastic wear pads on the press ram replaced

Pre-press:

Both bearings on the pre-press shaft replaced.

Both hydraulic cylinders dismantled, disassembled and partially overhauled, both cylinder tubes honed, complete seal sets replaced, leak test performed.

Scraper flap on the pre-press replaced.

Binding system:

Two complete needles with wire deflection rollers replaced

Needles adjusted and set

All wire deflection rollers in the needle heads replaced

Drill fingers replaced

Two drill shafts replaced

All 8 wear plates on the Drillomat, under the drill fingers, replaced

Scope of delivery:

Only the baler will be sold.

The documentation (Manual, CE-declaration, electr./hydr.-drawings), are completely available. Inspections are possible after agreement. We will not assume liability for the given technical data and possible errors.

Dokumen

Pembekal

Nota: Daftar secara percuma atau log masuk, untuk mengakses semua maklumat.

Hantar permintaan

Telefon & Faks

+31 597 2... iklan

Iklan-iklan ini juga mungkin menarik minat anda.

Iklan kecil

Kaufungen

Kaufungen

9,817 km

Unit traktor standard

MERCEDES-BENZActros 1845 SZM 4x2 Streamspace *Retarder

MERCEDES-BENZActros 1845 SZM 4x2 Streamspace *Retarder

Iklan kecil

Vechta

Vechta

9,895 km

Mencarik tumbuhan

MetsoM&J 4000S

MetsoM&J 4000S

Iklan kecil

Wülfrath

Wülfrath

9,997 km

Teknologi Pemisahan

DoppstadtSM 620 Plus

DoppstadtSM 620 Plus

Iklan kecil

Lanaken

Lanaken

10,098 km

Barisan pengeluaran kertas 4800 mm

Beloit

Beloit

Iklan kecil

Karlholmsbruk

Karlholmsbruk

9,301 km

Chipper

Söderhamn Eriksson670-56

Söderhamn Eriksson670-56

Iklan kecil

Fohnsdorf

Fohnsdorf

9,469 km

Akhbar sekerap

ATM Recyclingsystems GmbHPaketierpresse SP 100 AK-2

ATM Recyclingsystems GmbHPaketierpresse SP 100 AK-2

Iklan kecil

Lagedi

Lagedi

8,884 km

Bekas tekan

HusmannSPB 20 SEN-E

HusmannSPB 20 SEN-E

Iklan kecil

Velbert

Velbert

9,991 km

Baler

Presona ABLP 80 VH1

Presona ABLP 80 VH1

Iklan kecil

Tata

Tata

9,198 km

Saluran baler Pal Pacomat V 50t

PAAL PACOMAT V50ton 500kg bale

PAAL PACOMAT V50ton 500kg bale

Iklan kecil

Lagedi

Lagedi

8,884 km

Bekas akhbar alat tulis

HusmannSI- SEL- V2

HusmannSI- SEL- V2

Iklan anda telah berjaya dipadamkan

Berlaku ralat