Kemudahan prarawatanKlöpper

Vertical washer 2600 R-L

Kemudahan prarawatan

Klöpper

Vertical washer 2600 R-L

Tahun pembuatan

2021

Keadaan

Terpakai

Lokasi

Maasmechelen

Gambar menunjukkan

Tunjukkan peta

Data mesin

- Nama mesin:

- Kemudahan prarawatan

- Pengeluar:

- Klöpper

- Model:

- Vertical washer 2600 R-L

- Tahun pembuatan:

- 2021

- Keadaan:

- hampir baru (terpakai)

- Fungsi:

- berfungsi sepenuhnya

Harga & Lokasi

- Lokasi:

- Breitwaterstraat 22, 3630 Maasmechelen, Belgique

Hubungi

Butiran tawaran

- ID iklan:

- A19111716

- Nombor rujukan:

- S-WSH-Klöpper

- Kemas kini:

- terakhir pada 09.05.2025

Penerangan

Vertical infeed transport

- Vertical 2600 mm washing machine with drying

- Tilting table (behind the washing machine)

- Horizontal outfeed transport

- tilting table (discharge)

Description of Line Components

Pos. 1 Loading station, 250kg

With the help of the suction frame, the sheets are taken off the glass rack and they are placed vertically on the tilting table in front of the washing machine. Differences in inclination can be compensated for by tilting the suction frame. The suction frame has a rotating function to collect short formats in an upright position and to place them down on the long edge.

Light crane

Trolley crane with a lift system traveling on rails by hand, which are standing on steel supports.

lift

Electrical lifting and lowering, horizontal turning and tilting of loads.

Generation of vacuum via vacuum pump system with check and display of the vacuum power.

A central operation desk with integrated control buttons allows easy signal activation of the single functions. In case of pressure loss in the dangerous area, it is displayed and acoustic signal is given.

Pos. 2 Vertical Inlet Transport WM

The vertical transport serves as inlet transport in front of the washing machine.

In horizontal position, the glass sheets are placed on Vulkollan transport rollers.

In vertical position transport rollers with Perbunan rings are driven via screw wheels. The transport rollers are arranged in drag bearings placed on a solid welded frame.

Small glass sheets are placed manually on the transport frame. After placing the glass sheet, the transport is activated by push button.

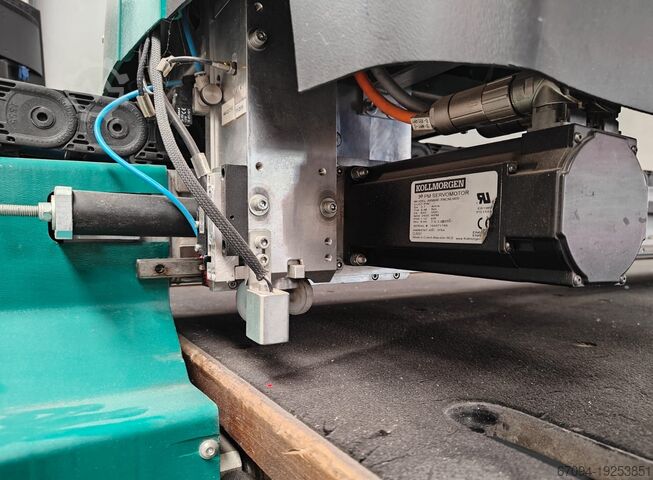

Pos. 3 Vertical Washing Machine with Drying

The washing machine body, washing chambers, recirculation vats and the drying nozzles are made entirely of stainless steel.

The rubber rings of the transport rollers are resistant to cutting oil.

Flat jet spraying nozzles in the pre-rinsing section are fed with city water. Coarse dirt particles removed are directly led into the drain. This reduces contamination of the DI-water circuit for the washing machine.

The washing machine is equipped with energy and water saving cascade system.

Pre-rinsing section with

Flat jet spraying nozzles

Washing section with

3 pairs of brushes,

3 vats and

3 pumps

Acid section with

1 pair of brushes,

1 vat and

1 pump

Drying section with

2 pairs of drying nozzles provide dry edges.

Pos. 4 Vertical Inspection Transport with glass Activation Section

The transport serves as Activation Section for the glass surface and as Inspection and Storage Transport before the Tilting Table.

Driven by a geared motor, A.C., frequency-controlled. All the rollers are arranged in drag bearings with a single drive operating pairs of spiral-toothed gear wheels.

Pos. 5 Tilting Table with Horizontal Transport and Vertical Inspection

Transport rollers, which are individually driven by worm gear wheels are placed on a solid welded frame. The transport rollers are arranged in drag bearings.

Tilting arms are in horizontal position. The integrated tilting table is made of several profile arms which can be tilted (electro-mechanical by crank mechanism) from the horizontal position by 84°. The tilting speed has its lowest speed at the beginning and at the end of the movement. The glass is tilted from vertical to the horizontal position. If no glass happens to be in the Pre-Heating oven the glass runs into the oven.

Lhedpfx Afowii Hfegob

Iklan ini diterjemahkan secara automatik. Mungkin terdapat kesilapan terjemahan.

- Vertical 2600 mm washing machine with drying

- Tilting table (behind the washing machine)

- Horizontal outfeed transport

- tilting table (discharge)

Description of Line Components

Pos. 1 Loading station, 250kg

With the help of the suction frame, the sheets are taken off the glass rack and they are placed vertically on the tilting table in front of the washing machine. Differences in inclination can be compensated for by tilting the suction frame. The suction frame has a rotating function to collect short formats in an upright position and to place them down on the long edge.

Light crane

Trolley crane with a lift system traveling on rails by hand, which are standing on steel supports.

lift

Electrical lifting and lowering, horizontal turning and tilting of loads.

Generation of vacuum via vacuum pump system with check and display of the vacuum power.

A central operation desk with integrated control buttons allows easy signal activation of the single functions. In case of pressure loss in the dangerous area, it is displayed and acoustic signal is given.

Pos. 2 Vertical Inlet Transport WM

The vertical transport serves as inlet transport in front of the washing machine.

In horizontal position, the glass sheets are placed on Vulkollan transport rollers.

In vertical position transport rollers with Perbunan rings are driven via screw wheels. The transport rollers are arranged in drag bearings placed on a solid welded frame.

Small glass sheets are placed manually on the transport frame. After placing the glass sheet, the transport is activated by push button.

Pos. 3 Vertical Washing Machine with Drying

The washing machine body, washing chambers, recirculation vats and the drying nozzles are made entirely of stainless steel.

The rubber rings of the transport rollers are resistant to cutting oil.

Flat jet spraying nozzles in the pre-rinsing section are fed with city water. Coarse dirt particles removed are directly led into the drain. This reduces contamination of the DI-water circuit for the washing machine.

The washing machine is equipped with energy and water saving cascade system.

Pre-rinsing section with

Flat jet spraying nozzles

Washing section with

3 pairs of brushes,

3 vats and

3 pumps

Acid section with

1 pair of brushes,

1 vat and

1 pump

Drying section with

2 pairs of drying nozzles provide dry edges.

Pos. 4 Vertical Inspection Transport with glass Activation Section

The transport serves as Activation Section for the glass surface and as Inspection and Storage Transport before the Tilting Table.

Driven by a geared motor, A.C., frequency-controlled. All the rollers are arranged in drag bearings with a single drive operating pairs of spiral-toothed gear wheels.

Pos. 5 Tilting Table with Horizontal Transport and Vertical Inspection

Transport rollers, which are individually driven by worm gear wheels are placed on a solid welded frame. The transport rollers are arranged in drag bearings.

Tilting arms are in horizontal position. The integrated tilting table is made of several profile arms which can be tilted (electro-mechanical by crank mechanism) from the horizontal position by 84°. The tilting speed has its lowest speed at the beginning and at the end of the movement. The glass is tilted from vertical to the horizontal position. If no glass happens to be in the Pre-Heating oven the glass runs into the oven.

Lhedpfx Afowii Hfegob

Iklan ini diterjemahkan secara automatik. Mungkin terdapat kesilapan terjemahan.

Pembekal

Nota: Daftar secara percuma atau log masuk, untuk mengakses semua maklumat.

Didaftarkan sejak: 2019

Hantar permintaan

Telefon & Faks

+32 89 53... iklan

Iklan-iklan ini juga mungkin menarik minat anda.

Iklan kecil

Zielona Góra

Zielona Góra

9,400 km

Mesin pertukangan kayu

BOOSTONER-02

BOOSTONER-02

Iklan kecil

Maasmechelen

Maasmechelen

10,092 km

Meja potong kaca

Bottero353BKM-J

Bottero353BKM-J

Iklan kecil

Maulbronn

Maulbronn

9,897 km

Pusat pemesinan bar

elumatecSBZ 150

elumatecSBZ 150

Iklan kecil

Maasmechelen

Maasmechelen

10,093 km

Ketuhar laminating kaca

FoursLamination Furnace

FoursLamination Furnace

Iklan kecil

Scerne

Scerne

9,533 km

Pusat pemprosesan Emmegi

EmmegiPhantomatic T4 A

EmmegiPhantomatic T4 A

Iklan kecil

Mühlacker

Mühlacker

9,892 km

Pusat pemesinan berterusan

FederhennSBZ-100

FederhennSBZ-100

Iklan kecil

Jerman

Jerman

9,760 km

Sistem basuh kaca

BohleVertiClean 16.4-20

BohleVertiClean 16.4-20

Iklan kecil

Velžys

Velžys

8,852 km

Meja senget kaca

TRIULZI-IGTilting table

TRIULZI-IGTilting table

Iklan kecil

Brendola

Brendola

9,727 km

Lori dengan badan tetap

Iveco

Iveco

Iklan kecil

Estonia

Estonia

8,865 km

Pusat pemesinan

TeknaTKE783

TeknaTKE783

Iklan anda telah berjaya dipadamkan

Berlaku ralat